Non-woven Industrial Development. Non-woven fabric was developed in the petrochemical industry following the invention of plastic cloth (film). Compared with plastic cloth, it is less heavy and offers good ventilation. It is often used in medical and sanitary items such as facial towels, filtering, sanitary napkins etc. Later it was created and applied to engineering. Non-woven fabric is utilized in vegetable production to protect against damage from cold. The production process of non-woven fabric is different from plastic film, however the fundamental raw materials are nearly the same. This includes PE (polyvinylchloride), EVA(Ethylene Vinyl Acetate Copolymer) EVA/polyethylene, as well as PVA/polyvinylether. The standard plastic film is produced by melting the plastic then inflating it. In essence, the film is continuous; the material is able to stretch indefinitely. The film's surface is completely free of pores. It is a completely impermeable film which blocks the flow and exchange of molecules within the film. Due to the rapid growth of the textile industry synthetic chemical fibers derived from the mentioned raw materials substituted for most natural plant fibers and were the hottest item in the textile industry. These chemical fibers are still used to make cloth by traditional weft and warp weaving. So-called non-woven material is formed by interlocking fibers on the same plane at various angles across all directions, instead of using traditional warp and weft methods. This material has better material properties than traditional weaving fabrics. It can also be produced in one process, from raw materials to finished products. This is a superior alternative to weaving, which involves drawing fibers. In the last few years, nonwoven fabrics have been used extensively in the fashion industry. Recently, due to advancements in material science and the development of production technologies Non-woven fabrics are becoming more varied and are used in greater and greater quantities. Diverse materials and products are evident in our daily lives. The increasing use of non-woven textiles in agriculture is mostly due to their lightness, ease of production, cost-effective, diversity, and wide variety of uses. Look at this non woven weed control fabric for advice.

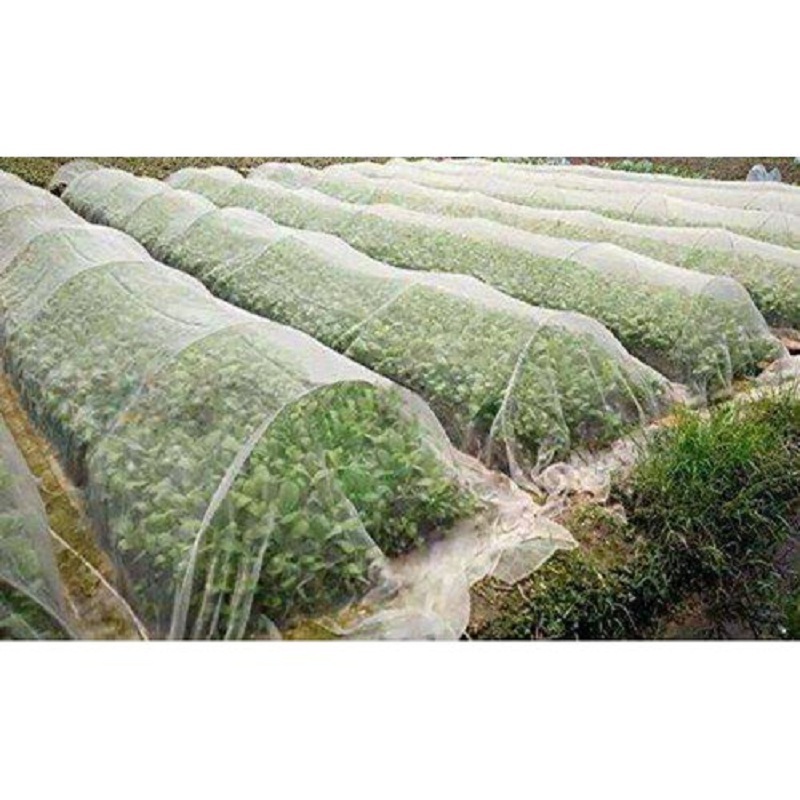

Non-woven Fabrics in the Agricultural Industry. Non-woven textiles first became popular in Europe in the year 1978. They were used to keep carrots warm in the early stages of harvesting, and to prevent whiteflies as well as tomato leaf viruses. Non-woven fabrics used in the United States to mulch cantaloupes. Sweet peppers. tomatoes. Root vegetables. Carrots. Radishes. Cabbage. Lettuce. It is used primarily to preserve heat, for early harvesting, as well as insect control. Non-woven fabrics are ideal for covering surfaces , such as grass-proof mats. They can also increase the temperature of soils by retaining water. A short fiber is utilized to make water-absorbing blankets which are sprayed on nursery beds in order to allow the roots to completely absorb water. They can serve as the basis to produce turf or lawn grass to moisten drain, divide, and spruce up the garden. They are utilized to grow large woody trees such as the fruit trees as well as garden trees. Non-woven fabrics are also used in Taiwan to cover crops. They are also used for the control of the environment in large greenhouses to conserve energy. Canopy curtains and double-layered curtains and canopy curtains reduce the radiation and heat loss in the evening. To shade and protect cauliflower bulbs, high-density nonwoven spun-bonded TAVIK fabrics were employed. Farmers quickly took to it because of its outstanding shading capability as well as its low thermal conductivity, easy recyclability and easy acceptance. Then, it was used for the preservation of heat and pest-proofing of leaf vegetables and the preservation of heat and shade and cultivation of fruit trees and pineapples. The growth of non-woven industries is slow because of Taiwan's unique ecosystem and climate. Taiwan's non-woven fabric makers continue to innovate non-woven technology. Their focus is on the permeability of air and water and water repellency. For its use in the preservation and storage of agricultural goods, it has stepped up its research and hopes to broaden the scope of applications. Follow this agriculture non woven fabric manufacturer for tips.